Blog Layout

Choosing the Right Cutting Tip for the Job

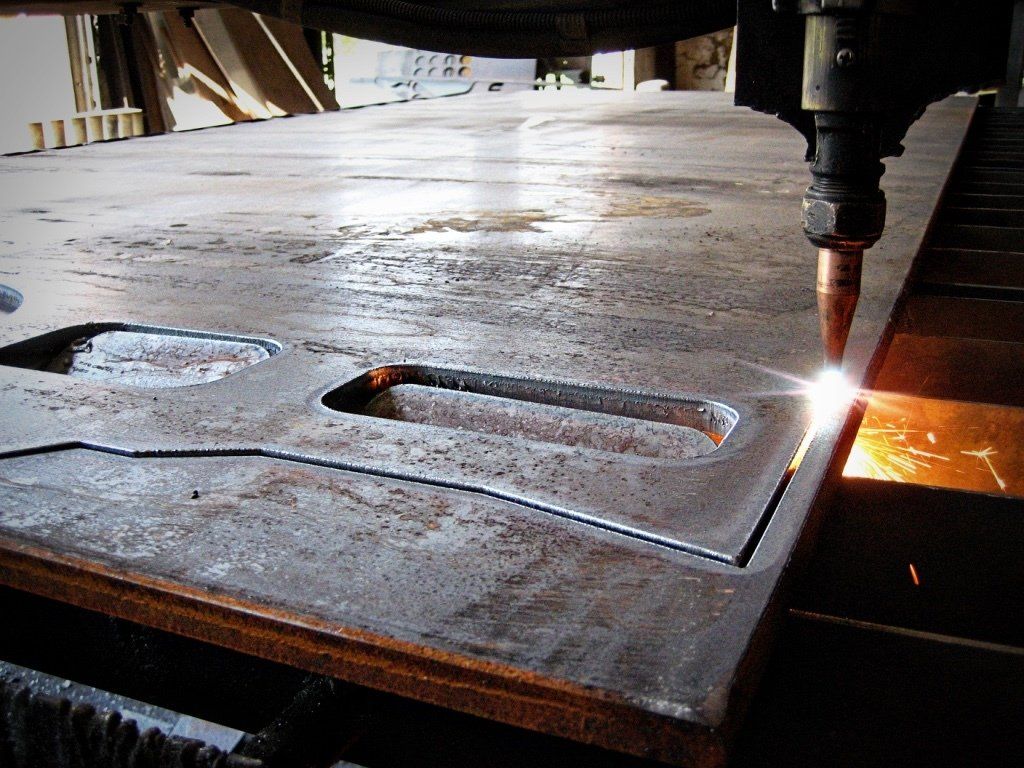

Selecting the right cutting or styling tool for the job means the difference between an average cut or a great cut. Therefore, it is important to choose carefully. It is critical to both performance and safety to choose the correct tip for the job. Here’s a simple step-by-step process for choosing the right cutting tip to ensure you deliver a great cut every time.

Choosing the Right Cutting Tip

Selecting the right cutting or styling tool for the job means the difference between an average cut or a great cut. Therefore, it is important to choose carefully. It is critical to both performance and safety to choose the correct tip for the job. Here’s a simple step-by-step process for choosing the right cutting tip to ensure you deliver a great cut every time.

Seat Type

The brand will determine the seat type. You must know the manufacturer or model of your torch and/or the part number of the tip you want to replace, which determines the seat type.

If you skip this step, damage to the equipment or dangerous flammable gas leakage can result. Also, tip seats vary greatly with torch model.

Metal Thickness

The size of the center hole of the cutting and gouging tip delivers the proper amount of oxygen at the proper pressure for a specific metal thickness.

Also, the size of the pre-heat orifice handles the proper amounts of mixed gas to heat a given thickness of metal adequately. Oxy-fuel equipment is capable of cutting mild steel from 3 mm (1/8″) to 300 mm (12″).

Application

The unique design of the tips determines the proper application use. There are different tips for cutting, gouging and heating. They may be one of the following:

- one-piece of solid copper

- two-piece hybrid with a brass inner piece and a copper outer piece

Additionally, some tips are designed specifically to use with automated cutting machinery for high-pressure cutting that permits the following type of cuts:

- quicker

- cleaner

- more accurate

Fuel Gas

There are numerous types of gases in oxy-fuel cutting operations. Each fuel gas utilizes a different cutting tip design.

They also optimize how the delivery of oxygen and gas occurs.

Acetylene

Acetylene is the hottest most-versatile gas. In addition, it is very easy to use for all purposes. Because the flame temperature is between 5,600 and 5,800°F, pre-heat time for cutting and gouging is relatively short.

However, this gas is the most expensive available and is not the most efficient for heating large areas.

Propylene

Propylene is common as a generic name for many types of gases. These range from specific gases—with their own chemical formulae—to gases that are primarily propane mixtures with ethylene or other chemicals that typically burn hotter than propane.

Cutting, gouging and heating can all require reasonable efficiency. While pre-heat times can be longer, using the proper tip design can eliminate this issue. Propylene yields flame temperature between 4,800 and 5,300°F. This gas is not common for welding.

Propane and Natural Gas

Propane and natural gas have flame temperatures between 4,500 and 4,600°F and are the least expensive gases available.

In addition, propane has a high BTU output and large heavy heating tips that are available. Therefore, it is the most efficient for heating. These gases are not used for welding.

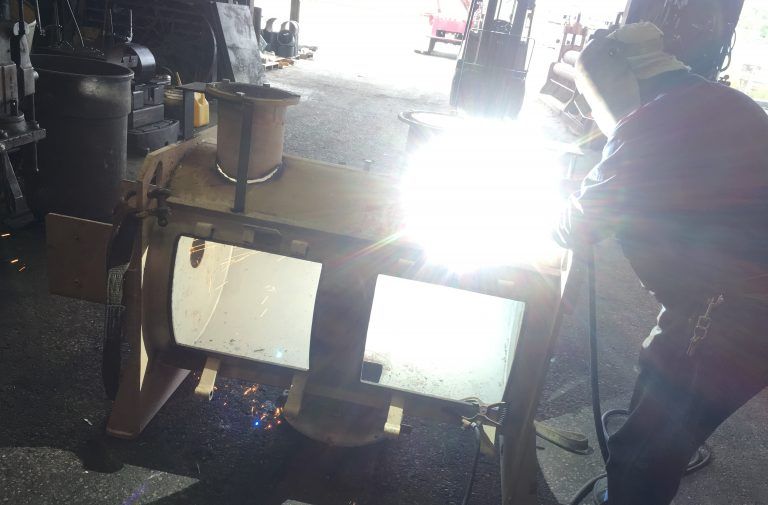

These are just the basics to consider when choosing the right cutting tip for the job. Brazos Industries, Inc. is a metal fabrication located in Bryan/College Station. With the help of our dedicated staff and loyal customers, we have grown into a company that serves a diverse array of industries. Over the years, the company has expanded and we continue to add capabilities of new machinery to satisfy growing customer needs. We carry a wide array of steel products for any of your current or future project needs. Contact us with the link below to purchase any of our products in inventory!

July 16, 2017

Many are unaware that drill bits require regular sharpening to give their best service. Similar to knives and axes, a dull drill bit requires much more force to do the same job. Instead of wearing the user out, a dull drill bit will inevitably wear out your drill. Giving your drill bits regular spot sharpening with a file is the best way to protect your investment in high-quality power tools. Brazos Industries knows the importance of properly sharpening drill bits, and we would like to share with you how to sharpen drill bits to protect your investment.

June 4, 2017

Eye injuries account for one-quarter of all welding injuries. This makes them by far the most common injury for welders, according to research from the Liberty Mutual Research Institute for Safety. Those most at risk for welding-related eye injuries are workers in industries that produce industrial and commercial machinery, computer equipment and fabricated metal products. Therefore, we will discuss the importance of safety glasses for welding.

April 30, 2017

Following a regiment of appropriate and thorough maintenance procedures allows a welding machine to run safely and dependably for a long time. Improper, incomplete or totally neglected maintenance can not only result in equipment failure, but it can also lead to serious hazards including severe injury or even death. With some forethought and basic planning, welding machine maintenance is extremely easy.

By localedge

•

April 9, 2017

Air arc gouging is a process of removing metal by using heat generated from a carbon arc. This process utilizes a carbon/graphite electrode, compressed air and a standard power source. The extreme heat arc created between the electrode and a metal workpiece gouges and melts the workpiece. The compressed air also blows away the molten metal. This process is common for cutting stainless steel, carbon steel and alloys of copper, brass, aluminum and magnesium.

By localedge

•

March 5, 2017

A good weld begins with good preparation, and good weld preparation begins with a clean cut. However, cutting is an art that requires both skill and knowledge of how to select and utilize the best grinding wheel for the job. The type of grinding wheel to use for a given application depends largely on what material you are cutting. We will discuss using the right grinding wheel for the welding job.

February 5, 2017

You can fit oxy-fuel torches with a “Cutting Head” and use them to cut one solid piece of metal into two or more pieces. Lighting, adjusting and shutting down an oxygen-acetylene torch is easy, particularly when following to proper procedures. We will discuss properly adjusting the flames for the oxy-fuel cutting.

January 15, 2017

A basic component of any welder’s toolbox is a decent angle grinder. There are few tools more versatile than a grinder. However, not all grinders are equal. Therefore, trying to choose the right one can be difficult. We will discuss a few tips for choosing the right grinder size for the job.